Using AI to Predict and Prevent Material Shortages in Construction

AI is revolutionizing the construction industry by enhancing the predictability and prevention of material shortages, a critical aspect of construction project management software. This blog post delves into how AI technologies are making a significant impact in mitigating the risks associated with material shortages, ensuring that construction projects are executed smoothly and efficiently.

Demand Forecasting and Planning

One of the fundamental benefits of AI in construction is its ability to provide accurate demand forecasts. Utilizing sophisticated algorithms, AI can analyze historical data, current market trends, and external factors, including seasonality, changes in customer preferences, and macroeconomic data. This capability helps project managers optimize inventory levels, thereby minimizing the risk of material shortages or excesses. By implementing construction financial management tools that incorporate AI, companies can significantly enhance their planning strategies.

Trend Analysis and Predictive Analytics

AI systems excel in processing vast amounts of data to identify patterns and trends indicative of future material shortages. For instance, by incorporating factors like weather forecasts, trade policies, and global economic events, AI can predict potential disruptions in the supply chain. This ability to perform predictive analytics empowers managers to take proactive measures to mitigate risks before they escalate, illustrating the importance of integrating AI-driven construction management tools in day-to-day operations.

Real-Time Inventory Tracking and Management

Jobsite management tools that leverage AI provide comprehensive insights into materials, tools, and equipment. Continuous monitoring of inventory through construction document management systems reduces instances of overstocking or stockouts. These tools ensure projects remain on course, preventing unexpected delays due to material shortages. Notably, Zepth offers innovative features that support real-time inventory tracking, ensuring that construction teams can access accurate and up-to-date information about materials at all times.

Optimizing Inventory Placement and Warehouse Management

AI also plays a critical role in optimizing inventory placement in warehouses. By ensuring better space utilization and reduced order fulfillment times, AI-driven systems can identify shortages or surpluses and automatically generate replenishment orders when necessary. This optimization process enables construction managers to maintain optimal workflow while ensuring that materials are readily available when needed, minimizing wastage and inefficiencies across projects.

Supplier Optimization

Choosing the right suppliers is essential in managing construction material shortages. AI can evaluate and select the best suppliers based on various criteria, including price, quality, delivery timeliness, and collaboration history. This ensures companies work with reliable suppliers, significantly reducing the risk of material shortages that could hinder project progress. Furthermore, establishing collaborative relationships with these suppliers can enhance project delivery and service quality.

Predictive Maintenance and Risk Mitigation

Integration of AI technologies can also enhance predictive maintenance strategies. By analyzing historical data, AI can predict potential equipment failures and their impact on material shortages, allowing teams to devise proactive maintenance strategies. Implementing construction risk management tools powered by AI enables real-time monitoring of the supply chain, allowing immediate responses to anomalies, and ultimately preventing costly production downtimes.

Integration with Supply Chain

AI-based management tools can seamlessly integrate with suppliers’ systems to ensure that materials are ordered, delivered, and replenished just in time. This integration minimizes the need for large storage spaces and significantly reduces the risk of material wastage due to spoilage or obsolescence. Organizations implementing comprehensive construction lifecycle management software will benefit immensely from enhanced coordination throughout the supply chain.

Key Benefits of AI in Construction

- Increased Efficiency: AI optimizes resource allocation, reducing the likelihood of material shortages and ensuring that projects are executed smoothly and on time.

- Cost Savings: Accurate demand forecasting and real-time inventory management assist in minimizing excess inventory and reducing storage costs.

- Risk Mitigation: AI’s predictive analytics and real-time monitoring capabilities help identify and mitigate potential risks associated with material shortages.

- Improved Safety and Quality: Preventing material shortages contributes to better safety and quality control throughout construction projects.

Use Cases of AI in Construction

AI’s application in construction spans various use cases, including:

- Construction Project Management: AI managed large-scale construction projects by predicting material needs, optimizing inventory, and ensuring timely material delivery.

- Supply Chain Optimization: Companies implement AI technology to select trustworthy suppliers and ensure just-in-time material delivery.

- Predictive Maintenance: AI is used to anticipate equipment failures and material shortages, facilitating proactive maintenance strategies and reducing downtime.

Best Practices for AI Implementation

- Data Integration: Ensure seamless integration of data from various sources to enhance AI predictions.

- Continuous Monitoring: Employ real-time monitoring systems to promptly detect anomalies and take corrective actions.

- Supplier Collaboration: Maintain strong relationships with suppliers to streamline integration with AI-driven supply chain management systems.

Emerging Innovations in AI and Construction

The industry is witnessing exciting innovations, including:

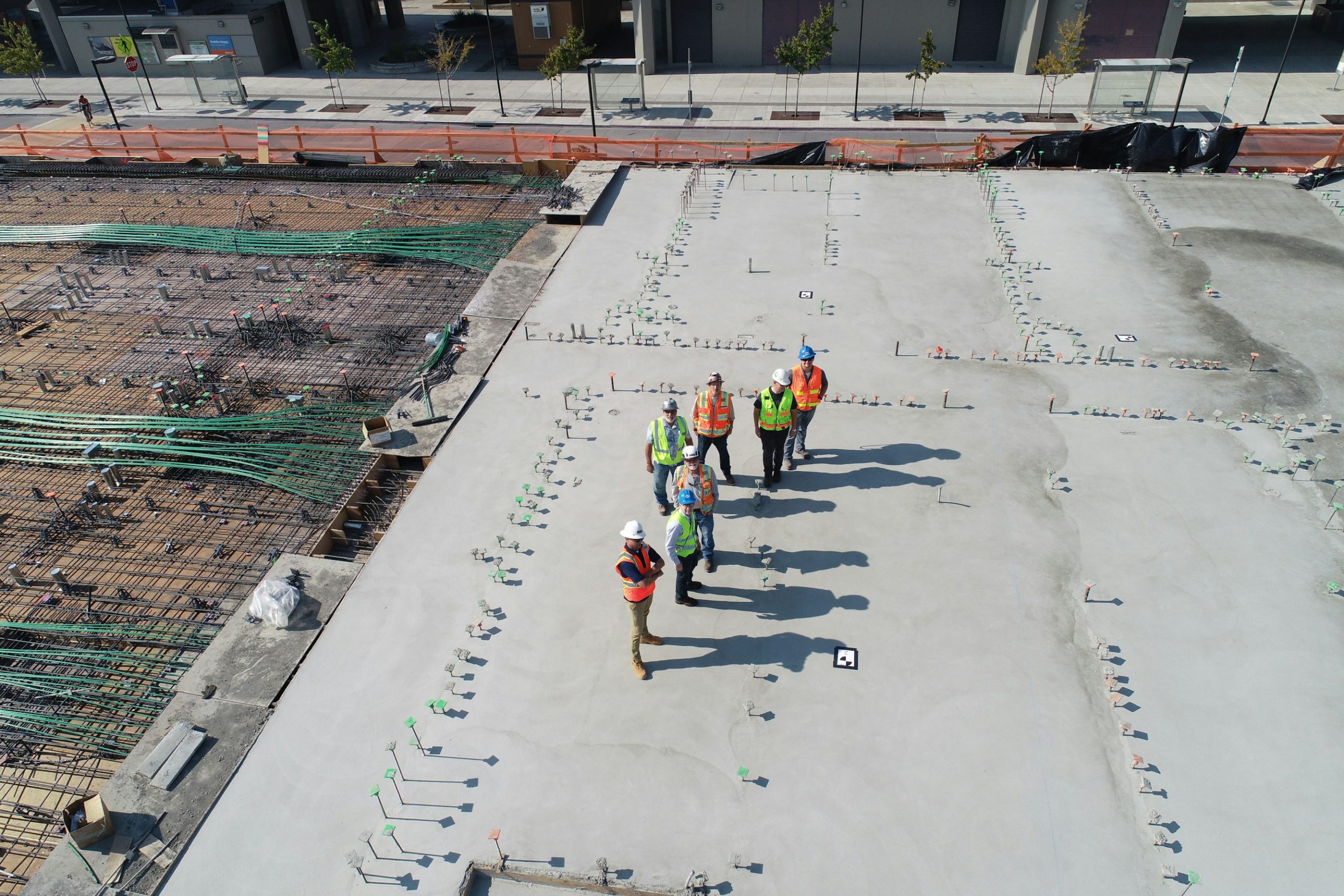

- AI-Powered Drones and Sensors: Increased use of AI-driven technology like drones for real-time monitoring of construction sites.

- Cloud-Based Collaboration Platforms: AI-enhanced cloud solutions improve communication and data sharing among project stakeholders.

How Zepth Can Help

Zepth is at the forefront of AI implementation in construction, offering a range of tools to address material shortages and streamline operations:

- Supply Chain Management: Zepth’s AI-driven tools streamline supply chain processes and ensure timely delivery of materials.

- Predictive Analytics: Our predictive analytics capabilities can accurately forecast material needs while identifying potential risks.

- Real-Time Monitoring: Continuous tracking of inventory levels allows for proactive responses to shortages.

- Resource Allocation: Zepth’s AI systems optimize resource allocation, ensuring the right materials are available exactly when needed.

By leveraging AI in these transformative ways, construction companies can enhance their ability to predict and prevent material shortages, leading to more efficient and successful project outcomes. For more insights, check out Zepth’s AI Solutions for Construction.